Colour measurement in food industry is an important quality attribute of food products which influences consumer's choice. Food scientist, food processors and marketers want the food to look appealing and consistent.

Food processors use colour measuring instrument for checking and standardizing ingredient colour so that they can control colour of their final products, and analyse colour change in processing, transportation and storage .Also to communicate colour indices to their supply chain.

Products in food industry can be in different shape / size, powder or granule, liquid or paste or solid, transparent or opaque.

Based on optical characteristics, food products are classified as

Opaque and translucent products are measured by reflection principle where as transparent products by transmission principle.

Two principles are employed in colour measurement viz. colorimetry and spectrophotometry.

1. Colorimetry quantifies colour by measuring three primary colour components of light which are seen by the human eye i.e, red, green and blue. In this principle secondary and tertiary colours like yellow, orange are not individually quantified. Instruments using colorimetry principle are generally called chronometers or colorimeter. They measure the colour much the same as human eye.

2. In spectrophotometry the spectral reflectance or transmittance of a product is measured across the full spectrum of visible light ( 400 nm to 700 nm ) to provide precise and accurate measurement. Instruments using this principle are called spectrophotometer. They are used in formulation and quality control of desired colours in prepared food products, in research and development of new products etc.

There are various colour indices and the popular is L*, a*, b* recommended by CIE. Colour measurement instruments comes with different apertures, illumination. Selection of instruments depend upon the type of food product and application. Instruments are available in portable, bench top and inline model, which food processors can choose depending upon the application.

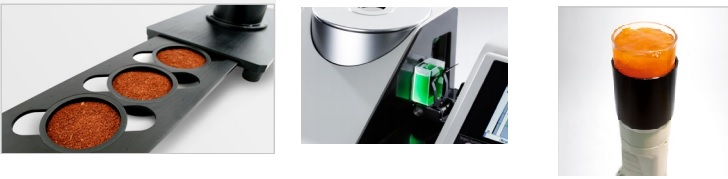

Consistent sample presentation is important for accurate measurement. Manufacturer of colour measuring instruments provide different accessories like glass cells, petri dishes, sample holders to assist users to reduce sample preparation time and obtain repeatable measurements.

Accessories for holding samples

New generation colour measuring instruments are easy to operate with large colour screen. USB port that allow users to configure and store different profiles. Colour quality control software are available to record all measurement data, analyze the results and generate customized reports.

Colour quality control software Spectra Magic NX

Colour measurement instruments are widely used in virgin coconut oil production, desiccated coconut, chocolate, milk powder, surmi processing, peanut butter, tomato ketchup, orange juice, soft drinks, cereals, bakery and meat segments of food industry.

Image courtesy : Konica Minolta Sensing Singapore Pte Ltd.